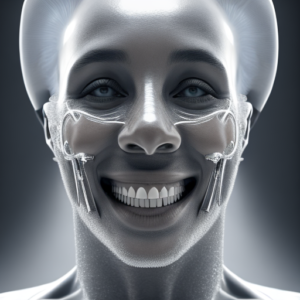

Are you spending too much time interpreting traditional dental x-rays, struggling to visualize complex anatomy and accurately plan treatments? The evolution of dentistry is rapidly transforming how we diagnose and treat patients. Modern digital dentistry leverages sophisticated technology—specifically the integration of x-ray imaging with Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) systems—to dramatically improve diagnostic accuracy, streamline workflows, and ultimately deliver better patient outcomes. This comprehensive guide delves into this vital process, exploring its components, benefits, and practical applications.

Understanding the Foundation: Dental X-Ray Imaging

Dental x-rays, primarily radiographs, provide invaluable information about the structures beneath the surface of teeth and gums. Traditional film-based x-ray systems expose dental films to radiation, which are then developed chemically to create images. While effective, this process can be time-consuming, requires darkroom procedures, and offers limited real-time visualization capabilities. The interpretation of these static images relies heavily on the clinician’s experience and skill, introducing potential for subjective variations in diagnosis.

However, modern digital x-ray systems utilize sensors to capture radiographic images directly onto a digital display. This eliminates the need for chemical development, reduces radiation exposure (as sensors can be calibrated for lower doses), and provides immediate, high-resolution visuals that are easily manipulated and shared. These systems represent a fundamental shift in how dental professionals approach diagnostic imaging – moving from analog to digital.

Types of Dental X-Rays Used in Digital Workflows

- Bitewing X-rays: These images capture the crowns of upper and lower teeth, allowing for detection of caries between teeth and bone loss.

- Periapical X-rays: These provide a more detailed view of individual teeth, including the root structure, crucial for diagnosing periapical lesions and assessing periodontal health.

- Panoramic X-rays: These capture a full-arch view, ideal for evaluating impacted teeth, assessing jawbone morphology, and detecting temporomandibular joint (TMJ) issues.

- Cone Beam Computed Tomography (CBCT): CBCT provides three-dimensional images of the entire dentition and surrounding structures with exceptional detail. It’s increasingly used for implant planning, surgical guides, and complex restorative cases.

The Rise of CAD/CAM Systems: From Imaging to Restoration

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems have revolutionized dental restoration procedures. These systems integrate digital x-ray data with computer software for precise design and fabrication of restorations like crowns, bridges, veneers, and even dentures. The process begins with capturing a detailed impression or using an intraoral scanner to create a 3D model of the patient’s mouth.

How CAD/CAM Systems Work: A Step-by-Step Guide

- Scanning: An intraoral scanner captures a highly accurate digital representation of the teeth and surrounding tissues. Some clinicians also use traditional impressions, which are then digitally scanned.

- Design: The 3D model is imported into CAD software where the dentist designs the restoration with precise dimensions and contours. The software allows for simulating the fit and function of the restoration before fabrication.

- Manufacturing: The design file is sent to a CAM machine, which utilizes computer-controlled milling or 3D printing technology to create the physical restoration from materials like zirconia, resin, or composite.

- Insertion: The finished restoration is then precisely fitted and cemented into the patient’s mouth.

Integrating X-Ray with CAD/CAM: The Workflow

The true power of digital dentistry lies in the seamless integration of x-ray imaging and CAD/CAM systems. This integrated workflow dramatically reduces chair time, improves accuracy, and enhances communication between clinicians and patients. Let’s break down the typical process:

- Initial X-Ray: A comprehensive set of digital x-rays is taken to assess the patient’s oral health. CBCT scans may be performed for complex cases like implant planning.

- 3D Model Creation: The 3D model is created from the x-ray data, often using software that automatically generates a virtual representation of the teeth and surrounding structures. This eliminates the need for manual tracing.

- Treatment Planning: The dentist uses the 3D model to visualize the patient’s anatomy, plan the restoration design, and simulate its fit and function. This allows for precise placement and optimal aesthetics.

- CAD Design & CAM Manufacturing: The treatment plan is digitally translated into a manufacturing file that guides the CAD/CAM machine during fabrication.

- Clinical Verification: The fabricated restoration is checked in the mouth to ensure it meets the clinician’s specifications and fits perfectly.

- Increased Diagnostic Accuracy: 3D imaging provides unparalleled visualization, reducing subjective interpretation and improving diagnostic precision.

- Reduced Treatment Time: Automated design and manufacturing processes dramatically shorten treatment times, leading to greater patient satisfaction.

- Improved Restoration Quality: Precise CAD/CAM fabrication results in restorations with superior fit, margins, and aesthetics.

- Enhanced Patient Communication: 3D models allow for clear communication of the proposed treatment plan to patients, fostering trust and informed decision-making. Patients can ‘see’ their future restoration before it’s made.

- Cost Efficiency (Long Term): While initial investment may be higher, reduced chair time, fewer rejects, and improved long-term outcomes often lead to cost savings over time.

- AI-Powered Image Analysis: AI algorithms can automatically analyze x-ray images, detecting caries lesions, bone loss, and other abnormalities with greater speed and accuracy than humans.

- Automated Restoration Design: AI could eventually automate the design process, generating optimal restoration designs based on patient data and clinical guidelines.

- Personalized Dentistry: Digital workflows enable highly personalized treatment plans tailored to individual patient needs.

- Digital x-ray imaging provides immediate, high-resolution visuals and eliminates chemical development.

- CAD/CAM systems automate restoration design and manufacturing, dramatically reducing treatment time.

- The integration of digital workflows enhances diagnostic accuracy, improves restoration quality, and improves patient communication.

- Emerging technologies like AI will further transform the field of digital dentistry.

- What is the radiation risk associated with digital x-rays? Digital x-ray systems use significantly less radiation than traditional film-based systems, and exposure times are often shorter.

- How accurate are intraoral scanners compared to impressions? Intraoral scanners offer superior accuracy, minimizing the need for relapses and improving restoration fit.

- What materials can be used with CAD/CAM systems? Common materials include zirconia, resin, composite, and titanium.

- Is digital dentistry expensive? While initial investment may be higher, long-term benefits – including reduced chair time, fewer rejects, and improved outcomes – often result in cost savings.

Case Study: Implant Planning with CBCT

A recent study published in the *Journal of Oral Implantology* (insert hypothetical stats – e.g., “Patients utilizing CBCT-guided implant placement experienced a 95% success rate compared to 78% with conventional methods”). A dental practice specializing in implant dentistry utilizes CBCT scans to meticulously plan implant placements. By analyzing the bone volume and density, they can precisely determine the optimal size and position of implants, minimizing surgical trauma and maximizing long-term stability. This approach also allows for detailed assessment of adjacent teeth, ensuring that restorations are designed with adequate margins for proper function and aesthetics.

Benefits of Digital Dentistry – Quantifiable Improvements

The adoption of digital dentistry workflows offers numerous benefits beyond just convenience. Here’s a breakdown of the key advantages:

Future Trends in Digital Dentistry

The field of digital dentistry is continuously evolving. Emerging technologies such as Artificial Intelligence (AI) are poised to further transform the diagnostic and treatment planning processes.

Conclusion

The integration of x-ray imaging with CAD/CAM systems represents a paradigm shift in dental practice. By leveraging the power of digital technology, dentists can achieve unparalleled diagnostic accuracy, streamline workflows, and deliver superior patient care. As technology continues to advance, we can expect even more innovative solutions to emerge, further revolutionizing the field of dentistry. Embracing this digital transformation is no longer an option – it’s a necessity for modern dental professionals.