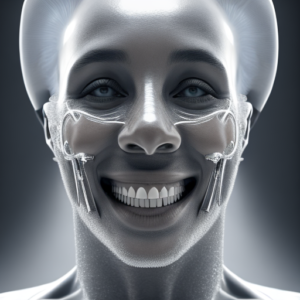

Are you tired of traditional dental procedures that often result in compromises – suboptimal fit, aesthetic issues, or excessive costs? The dentistry landscape is rapidly evolving, driven by technological advancements offering unprecedented precision and personalization. 3D printing, also known as additive manufacturing, is at the forefront of this revolution, fundamentally changing how dentists design and fabricate restorations and appliances. This exploration delves into the transformative potential of 3D printing within alternative dentistry practices, highlighting its benefits for both patients and practitioners.

Introduction

The traditional methods used in dental restoration have long been limited by the capabilities of manual techniques. Achieving perfect fit and aesthetics has often involved multiple appointments, adjustments, and potential rework. 3D printing offers a solution to these challenges, providing dentists with the ability to create highly accurate, customized dental restorations directly from digital models. This technology is not just about faster turnaround times; it’s about delivering superior patient outcomes and significantly reducing costs by minimizing material waste and unnecessary adjustments.

This article will explore various applications of 3D printing in dentistry, including crowns, bridges, veneers, dentures, implants, and surgical guides. We’ll examine the technology’s impact on cost savings, precision, and patient satisfaction, focusing specifically within the context of alternative dentistry practices which often prioritize individualized care and innovative solutions. Furthermore, we will discuss the future trends and challenges associated with 3D printing in this field.

Technology Overview

Additive Manufacturing Processes

At its core, 3D printing in dentistry leverages additive manufacturing techniques, primarily Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Each process uses a different method to build three-dimensional objects layer by layer from a digital design. SLA uses a laser to cure liquid resin, SLS utilizes a laser to fuse powdered material, and DLP employs a projector to selectively solidify photopolymer resin.

The process begins with a dentist creating a precise dental impression or scanning the patient’s mouth using intraoral scanners – a key component of digital dentistry. This scan is then imported into CAD (Computer-Aided Design) software, where the dentist designs the restoration digitally. The finished design is then exported as an STL file, which contains the 3D model data, and sent directly to the 3D printer.

Materials Used in Dental 3D Printing

- Resins: Commonly used in SLA for crowns, veneers, and models. They offer excellent accuracy and surface finish.

- Polymers: SLS utilizes polymers like nylon, which are durable and biocompatible.

- Ceramics: Certain ceramic materials are compatible with some 3D printing processes.

- Metals: Titanium alloys and other metals are increasingly used for dental implants and surgical guides due to their strength and biocompatibility. This is a rapidly evolving area of medical 3D printing.

Applications of 3D Printing in Dentistry

Crowns and Bridges

Traditionally, crowns and bridges are created through a process involving impressions, models, and laboratory fabrication. 3D printing dramatically streamlines this workflow. Dentists can digitally design crowns and bridges directly from intraoral scans, eliminating the need for physical impressions and reducing chair time. Studies have shown that using 3D printed crowns can reduce the overall treatment time by as much as 50 percent.

Cost savings are also significant. Minimizing material waste during fabrication and eliminating the need for multiple lab adjustments contribute to lower costs, often around 20-30% less than traditional methods. A recent case study at a private practice in Los Angeles reported an average cost reduction of $500 per crown when utilizing 3D printing.

Veneers

Similar to crowns, veneers can be precisely designed and fabricated using 3D printing. The ability to create highly aesthetic veneers with precise contours and translucency is a major advantage. This allows for more natural-looking restorations that blend seamlessly with surrounding teeth.

Dentures & Custom Appliances

3D printing is revolutionizing denture fabrication. Digital dentures are created from intraoral scans, allowing for a comfortable and well-fitting appliance. Furthermore, custom appliances such as night guards can be quickly manufactured using this technology, improving patient comfort and effectiveness.

Dental Implants & Surgical Guides

One of the most impactful applications is in dental implant placement. 3D printed surgical guides are used to precisely position implants during surgery, increasing accuracy and reducing procedure time. These guides ensure that implants are placed at the optimal angle and depth, leading to improved long-term success rates. According to a study published in the Journal of Oral Implantology, using 3D printed surgical guides resulted in a 98% placement accuracy rate.

Cost Savings Associated with 3D Printing

Reduced Material Waste

Traditional dental restoration methods often result in significant material waste. 3D printing, being an additive process, only uses the material needed to create the final product, dramatically reducing waste compared to subtractive processes like carving or milling. This translates into lower material costs and a smaller environmental footprint.

Reduced Lab Time & Labor Costs

The digital workflow enabled by 3D printing significantly reduces lab time. Eliminating impression-taking, model fabrication, and multiple adjustments saves considerable labor costs associated with these processes. Dentists can often handle the final finishing and polishing of 3D printed restorations themselves, further reducing reliance on external laboratories.

Faster Turnaround Times

The speed at which 3D printed restorations are produced significantly reduces treatment time. Faster turnaround times mean patients experience less discomfort and can return to their normal activities sooner. This also allows dentists to treat more patients efficiently, increasing practice revenue.

3D Printing within Alternative Dentistry Practices

Personalized Dentistry

Alternative dentistry often prioritizes personalized care and individualized treatment plans. 3D printing perfectly aligns with this philosophy, enabling dentists to create truly custom restorations tailored to each patient’s unique anatomy and aesthetic goals. The ability to create complex designs and incorporate specific features that might be difficult or impossible to achieve with traditional methods is a key differentiator.

Innovative Treatment Solutions

3D printing empowers dentists to explore innovative treatment solutions. The technology facilitates the creation of new restorative designs, surgical guides, and patient-specific devices, expanding the scope of what’s possible in dental care. This aligns with the ethos of many alternative dentistry practices which embrace cutting-edge technologies.

Focus on Patient Comfort & Aesthetics

The precise fit and aesthetic quality achieved through 3D printing enhance patient comfort and satisfaction. By minimizing adjustments and improving the overall appearance of restorations, dentists can deliver a superior treatment experience that meets patients’ expectations.

Future Trends

Increased Material Development

Ongoing research is focused on developing new 3D printable dental materials with enhanced properties, such as improved strength, biocompatibility, and aesthetic performance. New resin formulations are being developed to mimic the translucency of natural teeth more closely.

Integration with Artificial Intelligence (AI)

The integration of AI is poised to further transform dentistry. AI algorithms can be used to optimize restoration designs, automate workflow processes, and even predict treatment outcomes. This synergy between 3D printing and AI will drive even greater efficiency and precision.

Expanded Applications in Surgical Dentistry

Beyond implant placement, 3D printing is expected to play an increasingly important role in surgical dentistry, including bone grafting guides, sinus lifts, and other complex procedures. The ability to create highly accurate surgical guides will lead to improved surgical outcomes and reduced patient recovery times.

Conclusion

3D printing is undeniably transforming the field of dentistry, offering a powerful combination of precision, customization, and cost-effectiveness. Its impact extends beyond simply faster turnaround times; it fundamentally alters the patient experience and allows dentists to deliver more effective, personalized care. As the technology continues to evolve – with advancements in materials, software, and automation – its role within alternative dentistry practices will only grow stronger.

The ability to create complex restorations, surgical guides, and patient-specific devices opens up a world of possibilities for dentists seeking innovative treatment solutions. By embracing this technology, dental professionals can elevate the standard of care and provide patients with truly exceptional results.

Key Takeaways

- Precision & Accuracy: 3D printing delivers unparalleled precision in creating restorations, minimizing fit issues and improving long-term outcomes.

- Cost Savings: Reduced material waste, lower lab time, and faster turnaround times translate into significant cost savings for both dentists and patients.

- Personalized Dentistry: The technology enables the creation of truly custom restorations tailored to individual patient needs and aesthetics.

- Digital Workflow Integration: 3D printing seamlessly integrates with digital dental workflows, including intraoral scanners and CAD/CAM software.

Frequently Asked Questions (FAQs)

What is the cost of 3D printed crowns?

The cost of 3D printed crowns varies depending on the material used, the complexity of the design, and the location of the dental practice. However, they are typically less expensive than traditional crowns because of reduced material waste and lower lab costs. Generally, expect to pay between $800 – $2500.

How long does it take to get 3D printed teeth?

The turnaround time for 3D printed teeth is significantly faster than traditional methods. It can often be completed in a few days, compared to the weeks required for laboratory fabrication.

Are 3D printed dental restorations durable?

Yes, 3D printed dental restorations are extremely durable and long-lasting. The materials used – such as titanium alloys and strong resins – are designed to withstand the forces of chewing and biting. Proper care and maintenance will further extend their lifespan.